In LEAN lifts with 200k SKUs, the inventory management was highly complex and time-consuming. Additionally, the management of its stored goods required close attention.

Spare parts and tools kept in the LEAN lifts are critical in production.

Antra ID equipped every piece of equipment, tool, and spare part with RFID tags containing the items’ IDs. Additionally, Antra ID installed fixed RFID antennas in the LEAN lifts together with the controllers.

Whenever a lift tray arrives at the gate, the antennas capture the data of the items on the tray, supporting an automatic, continuous warehouse inventory.

The physical layer is linked to Antra ID’s proprietary, web-based MDC software platform, which feeds the data to a complex WMS that the Company also provides.

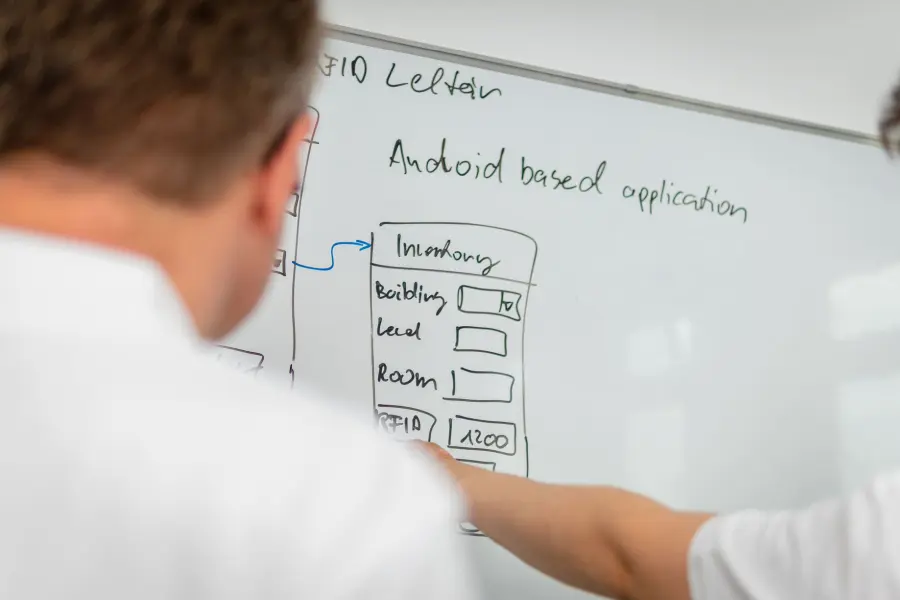

The data can be read by a dedicated RFID system (controllers, antennas, desktop RFID readers, handheld terminals), enabling automated identification at predefined places.

A manual inventory process follows automated inventory.

It reduced the stock-taking process’s time from 180 to 8 men days, resulting in a 22-fold efficiency increase.

The automated stock-taking process with a 98% hit rate.