A global German automotive customer uses temperature-sensitive and expensive adhesives, which can quickly lose their quality if their temperature reaches a certain level.

Antra ID developed a temperature logging system using RFID technology, utilizing the existing RFID gates. The manufacturing of this product is outsourced to a long-term partner.

A semi-passive RFID tag is placed in each box that contains the environmentally sensitive goods, and the tag collects data from its environment. Its operating temperature is between -55°C and +70°C.

Different external trigger events can be added to the log file.

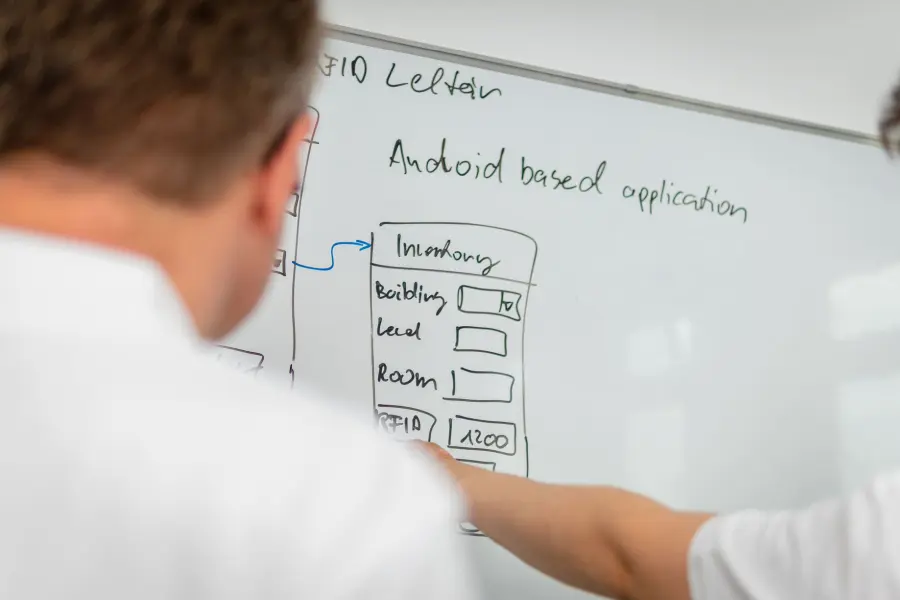

The data can be read by a dedicated RFID system (controllers, antennas, desktop RFID readers, handheld terminals), enabling automated identification at predefined places.

Easy integration and data exchange with different Warehouse Management Software.

Significantly reduced scrap products and time has been saved.

Responsibilities became transparent and verifiable, resulting in correct, auditable cooperation between supply chain partners.

Due to its success, the client has started introducing this solution worldwide in its manufacturing units.